The floriculture industry which encompasses the cultivation and sale of flowers, foliage, and ornamental plants, faces quite some significant environmental challenges. Traditional floristry practices often rely heavily on single-use plastics for packaging and transportation. And this contributes to waste and pollution. Simply put, the environmental impact of heavy reliance on traditional plastic—in whichever industry—is dire and detrimental. However, the emergence of circular plastic as a sustainable alternative presents an innovative and transformative opportunity for the flower industry. This novel innovation offers a promising solution; one that not only benefits the industry but also contributes to a more sustainable planet.

Understanding Circular Plastic

Circular plastic refers to a sustainable approach to plastic use that emphasizes recycling, reuse, and resource efficiency. Unlike the traditional linear model of plastic production—where plastics are created, used, and discarded—circular plastic aims to keep materials in use for as long as possible. This approach involves designing products for longevity, promoting recycling, and minimizing waste, thereby reducing the ecological footprint associated with plastic materials.

Photo by @dillewijn_zwapak

The Need for Circular Plastic in Floriculture

The floriculture industry relies on non-biodegradable plastics, which are used extensively in packaging, pots, and other materials. While convenient, this over-reliance on non-biodegradable plastics has affected the environment. Discarded plastic waste accumulates in landfills, oceans, and ecosystems, disrupting delicate natural balances and jeopardizing the very landscapes that the flower industry seeks to celebrate. This practice, therefore, not only contributes to environmental degradation but also poses challenges in waste management.

As the industry grows, so does the urgency to adopt more sustainable practices. Circular plastic, therefore, offers a solution by addressing these issues through innovative design and waste reduction strategies. It represents a fundamental shift in the way the flower industry—and people in general—approach plastic use.

Unlike the traditional linear model of production and disposal, the circular plastic model emphasizes recycling, reuse, and resource efficiency. It emphasizes the design of products for longevity, promoting recycling, and minimizing waste. Circular plastic, also, targets keeping materials in use for as long as possible.

What Are the Benefits of Circular Plastic in the Flower Industry?

Circular plastic—essentially a concept that is part of the broader circular economy—has many benefits that are far-reaching and positively impactful for the planet. This is, especially, true for the flower industry. Through circular plastic, the floriculture industry can significantly reduce the amount of plastic waste generated. This is achieved through the recycling of plastic materials into new products, thereby minimizing the need for virgin plastics and decreasing landfill contributions. The approach, also, promotes the efficient use of resources. By recycling and reusing materials, the industry can lower its energy consumption and reduce the environmental impact associated with plastic production. This efficiency is crucial in an industry that often faces high operational costs due to resource-intensive practices.

Likewise, while the floriculture sector has often been criticized for its negative impact on soil health due to the use of fertilizers and pesticides, often packaged in plastic, adopting circular plastic solutions means the industry can mitigate these effects. For instance, using biodegradable or recyclable packaging can reduce chemical leaching into the soil, promoting healthier ecosystems. there is, also, the element of consumer demand for sustainability, which is all about the growing consumer awareness regarding the environmental impact of products, including flowers. Adopting circular plastic practices means floriculture businesses can cater to this demand, enhancing their marketability. Relevant certifications and eco-labels associated with sustainable practices can attract environmentally conscious consumers, boosting sales and brand loyalty.

Also, the transition to circular plastic encourages innovation within the industry. Companies are increasingly collaborating with environmental organizations and researchers to develop sustainable packaging solutions. This collaborative approach not only enhances innovation but also creates a network of stakeholders committed to sustainability. A collaborative spirit can, also, lead to advancements in technology and processes that benefit the entire floriculture sector.

Broader Environmental Implications

The benefits of circular plastic, also, touch on spheres away from the floriculture industry. Reducing plastic waste and promoting recycling means circular plastic contributes to broader environmental sustainability goals. This approach aligns with global efforts to combat climate change and reduce pollution. For instance, the reduction of plastic waste can lead to lower greenhouse gas emissions associated with plastic production and disposal.

Photo by @circular_plastics

Moreover, the adoption of circular plastic can enhance biodiversity. This could be actualized by minimizing plastic pollution in ecosystems, and in turn, the floriculture industry helps protect wildlife and natural habitats. This is particularly important as plastic waste often ends up in oceans and waterways, posing threats to marine life and ecosystems.

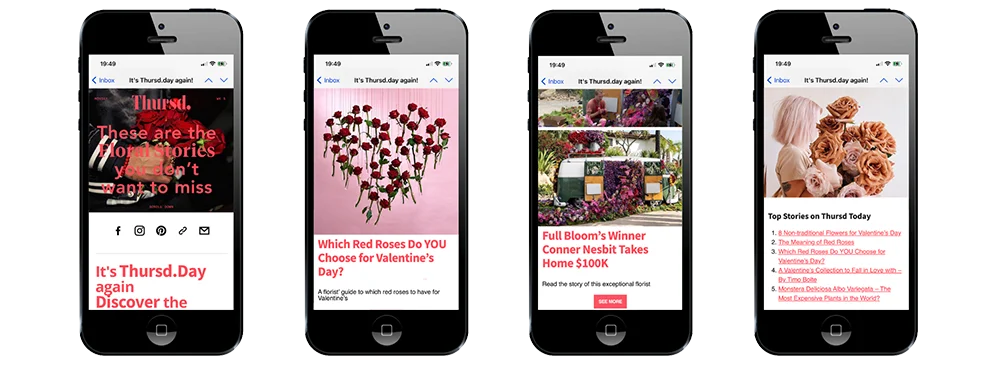

Circular Plastics: Upcycling to Enhance Sustainability in Floriculture

Aalsmeer-based Circular Plastics is a company keen on sustainable innovation, providing circular packaging and transport solutions that significantly reduce environmental impact, particularly in the flower industry. Focusing on a closed-loop system, Circular Plastics ensures that materials are continuously recycled, which minimizes the reliance on virgin resources and lowers the overall carbon footprint. The company has, essentially, set up a system in which polyethylene (PE) and polypropylene (PP) sleeve covers are 100% collected and 100% re-processed using modern upcycling technologies.

Photo by @circular_plastics

For instance, Circular Plastics collaborates with different stakeholders to create recycled labels and packaging that replace a substantial portion of virgin plastics with recycled materials. This not only conserves resources but also promotes a closed-loop system where materials are reused rather than discarded. Its innovations that use advanced technology not only conserve resources but also support the flower industry by providing eco-friendly products like flower boxes, pallets, and pallet boxes, floral films, and sleeves, collection products like the CircularBag, Circular sheets, and labels, all of which align with sustainable practices.

Circular Plastics:

"We [for instance] collaborated with Crea Green to produce recycled labels for pot plant grower Van der Salm. By using our new technology, a maximum of 80% of the virgin PP used has been replaced by PP recyclate."

The benefits of such innovations for the flower industry are numerous. Florists and growers can enhance their sustainability profiles by adopting these circular solutions, which resonate with environmentally conscious consumers. Also, by integrating Circular Plastics' products into their operations, businesses can reduce waste and promote a greener image, ultimately attracting more customers who prioritize sustainability. Moreover, Circular Plastics offers comprehensive product development services, guiding companies through the entire process from design to delivery. This support is crucial for individuals in the flower industry looking to transition to sustainable packaging without compromising quality or functionality.

Photo by Dillewijn Zwapak

A case in point is the collaboration with Circular in which Fresco Flowers has embraced the concept of circular plastic thus positively responding to reducing the one-off use of new plastics as much as possible. They make new foil from old flower sleeves, which are strong enough and sustainable. The foils are printed with organic inks and of course, protect the floral products during transport.

Circular Plastics, also developed the Eco Flower bag for bouquets and even a box made from upcycled plastics that keeps the flowers in optimal condition with a perfect microclimate during the entire transport. This reduces the damage to the flowers by 2% and improves the lifespan as an indicator of quality by 25%. The Eco Flowerbox (FECT®) by Circular is an innovative reusable flower box made of plastic waste and flower foil and replaces the one-off cardboard boxes. The Eco Flowerbox is light, ultra-strong, and also foldable, and therefore efficient for return freight and storage.

Photo by @circular_plastics

The innovative technology and high-quality recycling knowledge guarantee 7 years and 42 cycles for the Eco Flowerbox with sustainable savings on logistics costs and a positive impact on the CO2 footprint. And thanks to the smart closure, straps are unnecessary and the individual barcode and QR code ensure optimal tracking and tracing.

Header image by Dillewijn Zwapak