Lately, several factors, including climate change and resource depletion, have dominated global conversations. So, industries have continued to reimagine their practices to align with ecological sustainability and social responsibility. Floriculture, in particular, faces unique challenges—water scarcity, chemical overuse, and carbon emissions—that demand urgent innovation. As a result, Marginpar, the leading summer flower grower with farms spanning different countries, has for years been leading by example when it comes to sustainable floriculture practices.

The grower embeds sustainability into every facet of their floriculture operations, an idea that has, in turn, been continually showing how beautiful flowers and environmental management can coexist. Their comprehensive approach to sustainability spans ideals like water conservation, soil management, biodiversity protection, renewable energy adoption, waste reduction, and community engagement. This model both challenges and inspires the broader horticultural sector.

Continuously Embracing Sustainability

For Marginpar, the Japanese concept of Kaizen (referred to as Hamuka), which is about continuous improvement, has always been instrumental in driving their floriculture sustainability ideals. The grower’s farms always actively pursue benefits to the people and the environment in different ways.

As co-founder Richard 'Kiki' Fernandes puts it:

"We have implemented a Japanese method of working: Kaizen. This management system allows staff participation and recommendations for improved production and farm operations. All the employees, from management to the personnel in the field, develop a great sense of ownership in their work. As a result, the Marginpar Group has only a 2% turnover among its total staff (value-adders), and 50% of positions are filled by women."

So, how has Marginpar achieved all this? Well, the answer, to a great extent, lies in this very Kaizen concept, coupled with other factors. There is definitely a lot to learn from this grower.

A Nature-First Approach to Soil Health

One of Marginpar's key sustainability strategies is a keenness on soil health. The grower understands that healthy soils form the foundation of vibrant ecosystems and resilient plants and has, in turn, prioritized soil management practices that enhance rather than deplete this critical resource. In this regard, Marginpar has deliberately shifted away from conventional flower farming's reliance on synthetic chemicals, which provide quick fixes but ultimately compromise soil quality and ecosystem health.

Instead, the grower has adopted cultivation practices that work in harmony with natural processes, in a transition from chemical-intensive farming to nature-based solutions. This represents a significant paradigm shift in the flower industry, particularly in African contexts where immediate yields can sometimes take precedence over long-term sustainability. Maintaining their commitment to soil integrity, Marginpar ensures that their flower-cultivation land remains productive for generations, safeguarding both their business future and the environmental health of their farm locations.

Cover cropping between growing seasons has also become standard practice on Marginpar farms, preventing erosion while naturally replenishing soil nutrients. Plus, their approach to composting transforms plant waste into nutrient-rich soil amendments, which creates a circular system that reduces dependency on external inputs. Even more, regular soil testing informs customized management plans for each growing area by optimizing fertility while preventing nutrient runoff into surrounding ecosystems. Perhaps most impressively, Marginpar has implemented sophisticated rotation systems that prevent soil fatigue and naturally disrupt pest cycles, reducing the need for interventions while maintaining consistent production quality.

Waste Reduction, Resource-Efficiency, and Circular Economy

The flower industry generates substantial waste, from discarded stems to plastic packaging. Marginpar tackles this issue through a circular economy lens. Organic waste is composted and reintegrated into the soil, enriching it with nutrients and reducing the need for synthetic fertilizers. The specialized composting facilities process organic waste, transforming potential landfill material into valuable soil amendments.

The grower’s sustainability approach also encompasses other comprehensive waste management strategies across all operations. They follow the three pillars of responsible waste management: reduce, reuse, and recycle. Some practical examples of these pillars include:

- The use of worm tea as a natural fertilizer instead of synthetic alternatives (reduce)

- Old drip irrigation lines are reused for flower support structures (reuse)

- Plastic waste is transformed into new products. Broken buckets, for example, are recycled into plastic chairs (recycle)

As they note:

"We are serious about environmental improvements. Through resource-efficiency, cleaner production, promoting biodiversity, and environmental remediation. Kaizen teams measure resource usage and seek ongoing efficiency improvement. For example, the aqua check units enable precise monitoring of water levels in the soil. This ensures that water reaches the root zone efficiently—no more, no less.

What is more, storm and floodwater are harvested for re-use in lagoons. And to reduce the amount of pesticides used, they work with Integrated Pest Management (IPM). When it comes to pests, their motto is: "biology first, chemistry last." Their agronomist, Bobby Sandeman, explains: "We have taken a biological approach to counter resistant pests and diseases in a sustainable manner and by doing so also aim to re-set the natural soil ecosystem." One aspect of IPM is ‘spot spraying’. Flower pickers are trained to recognize types of pests, each presented by a different color flag. They plant the appropriate color flag where the pest was seen, and the pesticide is applied in that area only."

These interconnected initiatives have enabled Marginpar to significantly reduce its overall waste over the years and use the available resources efficiently, which positions the grower as one of the industry leaders when it comes to circular economy principles.

Water Conservation Practices

Water is the élan vital for horticulture and the general farming and cultivation industries. Yet its scarcity threatens ecosystems and livelihoods. On their different flower farms, Marginpar addresses the water challenge through a comprehensive approach to its conservation. The grower, for instance, deploys advanced drip irrigation systems that deliver precise amounts of water, minimizing waste and evaporation.

This precision-based approach delivers water directly to plant roots, reducing consumption by up to 60% compared to conventional spray methods. Complementing this system, Marginpar has constructed extensive rainwater harvesting facilities, including collection ponds and storage tanks that capture and store the commodity for use during drier periods.

Likewise, on all of their flower farms in Kenya and Ethiopia, they have implemented comprehensive wastewater treatment through specially constructed wetlands. The innovative system channels wastewater from multiple sources, including pack-houses, central spray units, fertigation units, canteens, laundries, and vehicle wash areas, into a sophisticated natural treatment process.

The treatment begins with deactivation tanks before routing the water to wetlands for purification. Within these constructed wetlands, the effluent passes through a vertical flow bed and a gravel bed system before reaching open surface ponds. Aquatic plants throughout the system help in this cause, while the ponds are treated to prevent underground seepage. Their commitment to water quality is evident in their monitoring practices that demand that if water does not meet quality standards, it is returned to the wetland system for additional treatment before being reused.

This closed-loop water system not only conserves water but also prevents agricultural runoff from contaminating local watersheds. The health of these water systems is monitored through ecological indicators, with the presence of aquatic wildlife like frogs and fish in the irrigation dams being the living indicator of water quality. Such initiatives have enabled Marginpar to significantly reduce its water consumption across several farms.

Biodiversity Protection and Enhancement

The grower recognizes all too well that biodiversity is essential for sustainable floriculture. Their farms, therefore, employ strategies that actively promote biological diversity within their ecosystems. Think of cover crops and rotating different types of flowers, which create natural habitats for beneficial insects and soil microorganisms. Their approach has multiple purposes: it enriches soil biology, reduces dependence on external inputs, and creates more resilient growing environments.

This shows how commercial flower production can contribute positively to local ecosystems rather than depleting them, with their farms now remaining productive lands that support both beautiful flowers and thriving ecological communities.

Furthermore, for the grower, chemical pesticides and herbicides are often replaced with integrated pest management (IPM) practices. It is commonplace for beneficial insects like ladybugs and lacewings to be introduced to control harmful species, while pheromone traps and bio-pesticides offer targeted solutions.

Harnessing Renewable Energy

Just like any other flower production enterprise, transitioning from fossil fuels to renewable energy is an important practice. This is also part of Marginpar’s sustainability strategy. Their various flower farms have green energy systems installed, including solar panels that convert sunlight into clean electricity to power systems like cold storage and others on their farms.

As CEO Rob Koning sums it up:

"We are proud members of FSI. Currently, 95% of our flowers are sustainably produced, and we are committed to reaching 100%. Sustainability is a continuous journey, one we are proud to embark on. It requires dedication, innovation, and responsibility. At Marginpar, we take a holistic approach to long-term sustainability, aligning with Environmental, Social, and Governance (ESG) principles to ensure a positive impact on the planet, our people, and the industry."

Essentially, the flower company has made it a priority to replace conventional lighting systems with power-efficient alternatives that maintain optimal conditions while systematically reducing carbon emissions. Energy-efficient lighting lights both growing areas and processing facilities, consuming a fraction of the power required by traditional lighting solutions.

People and Community Engagement and Social Responsibility

Marginpar recognizes that true sustainability encompasses social dimensions alongside environmental considerations. The grower has therefore established several projects that demonstrate their focus on community commitment alongside their flower production purpose. Their people-centric approach, based on the tagline: “We grow people, our people grow unique flowers,” is exemplified in this cause.

Marginpar:

“People are the backbone of our organization. For years, the Marginpar Group has been supporting communities around our flower farms. It’s where most of our employees and their families live. From the group’s core values, Marginpar believes that people are the backbone of the organization and the backbone of the community. From this belief, we want to empower people and support our local communities in growing their people and continuously improving their well-being. The Marginpar Foundation was founded to widen our community-oriented projects.”

The grower, therefore, engages with local communities through initiatives like school scholarships, clean water projects, and healthcare facilities. Investing in these community-focused initiatives helps break cycles and builds resilient communities capable of thriving alongside their farms. Furthermore, the grower adheres to strict ethical labor standards, ensuring fair wages, safe working conditions, and access to healthcare for its people, which creates stable livelihoods in rural communities where its farms are located.

Kiki Fernandes:

"We have a corporate social responsibility. Marginpar has already invested heavily in social matters in recent years. We assist the villages in the vicinity of our projects. We’ve helped build several schools and additional classrooms. We support children going to high school. We support the physically handicapped. We partner with the government concerning security issues. We provide different essentials to daycare centers. We also try to improve the roads. And if our employees make specific requests, we help them. Practical support, that's what it's all about for us."

Numerous Certifications as a Result

Marginpar has 17 farms across four countries: Kenya, Ethiopia (own farms), Tanzania, and Zimbabwe (partner farms). To ensure FSI compliance and sustainable practices, all their farms are certified across three areas: Environmental, Social, and GAP (Good Agricultural Practice). They use the term ESG (Environmental, Social, and Governance) to refer to the different aspects of sustainability.

Not all certifications are the same. For example, the MPS label is divided into three parts. MPS-ABC for the Environment component (where A+ is the highest attainable); MPS SQ for the social component, and MPS GAP for sustainable and safe farming practices. In comparison, the Kenya Flower Council label (KFC) has combined all three of these components into one certificate.

This is how their farms are certified:

- Kenya: 7 flower farms – KFC Silver Label

- Ethiopia: 3 flower farms – MPS-ABC (score A) & MPS-SQ & GlobalG.A.P.

- Tanzania: 3 partner farms– MPS-ABC (score A), MPS-GAP & MPS-SQ

- Zimbabwe: 4 partner farms – partly MPS certified and partly still in the certification process

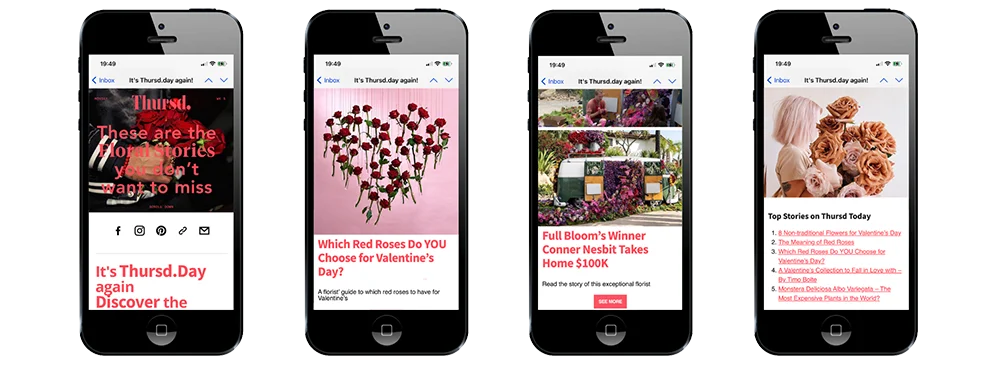

In this video, Farm Manager Peterson Thuita explains how his farm implements the concept of Kaizen (Continuous Improvement).

Photos and video by Marginpar (@marginpar).