In a market where greenery is often grouped under the same category, meaningful differences are shaped long before foliage reaches the supply chain. They begin at the source – through growing conditions, production discipline, and the standards applied at every stage of cultivation and handling. The way foliage is treated from plant to packing has a direct impact on consistency, reliability, and performance once it reaches its final destination.

At TAK, foliage production is guided by a clear philosophy: leaves are not interchangeable inputs, but agricultural products that require precision, accountability, and respect for process. Here's what separates their exceptional foliage from the rest.

TAK Foliage – Built on Climate, Process, and Consistency

Guatemala’s stable growing environment provides a strong foundation, while structured production systems and continuous measurement ensure dependable outcomes. This approach results in foliage that meets professional expectations in terms of uniformity, availability, and post-harvest behavior – qualities shaped by decisions made well before harvest day.

TAK concentrates on offering leaves with actual value, which is determined by quality, care, and performance, as opposed to manufacturing foliage as a commodity. Rich, bright, and stable coloration is made possible by Guatemala's natural environment, while TAK's infrastructure and manufacturing methods guarantee effectiveness and reliable outcomes at the destination. This combination allows for foliage that looks great and functions reliably over the course of its life.

Juan Cuellar, the Corporate Production Manager of the company, shares what differentiates their foliage from the rest of the market:

"The greatest differentiator is the passion with which we work at every level, along with the commitment to ensuring that every leaf that is cut is treated with respect for the person who will ultimately enjoy it. This mindset drives us to produce foliage that reflects true quality instead of only a commodity. In addition, Guatemala’s climate allows for very rich and deep coloration, and our infrastructure and process quality enable us to operate efficiently and ensure stronger performance at destination."

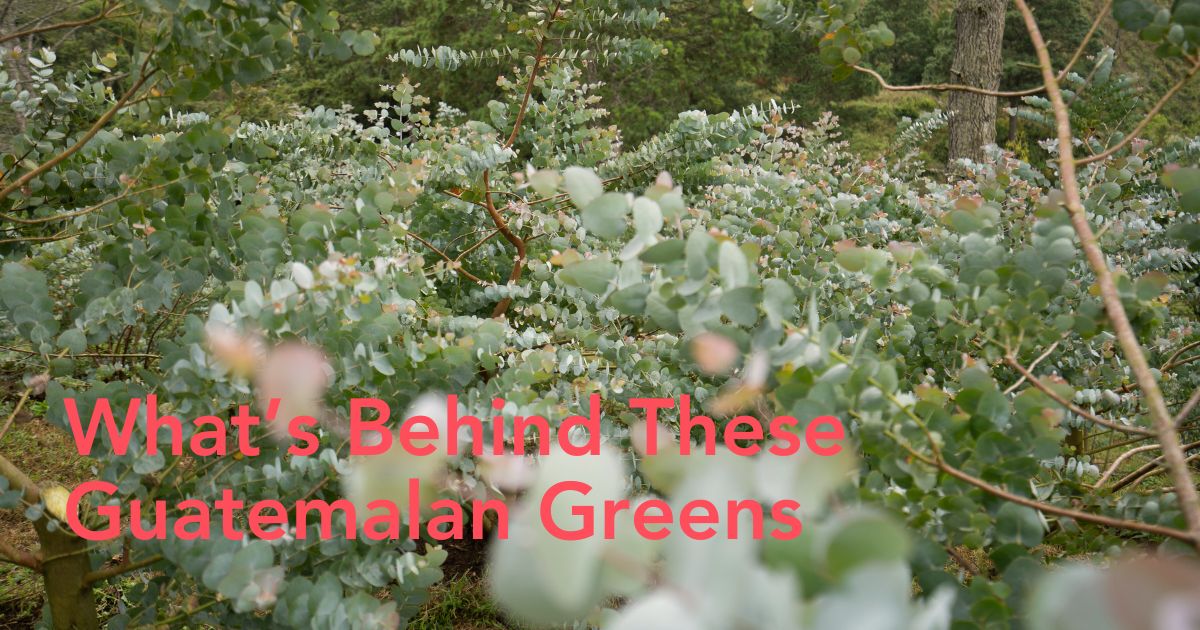

Guatemala’s Climate as a Strategic Advantage

Climate plays a defining role in foliage quality, influencing not only how plants grow, but how consistently they can be produced throughout the year. In Guatemala, long-term climate stability creates conditions that support continuous growth cycles and dependable supply, factors that directly impact quality and planning reliability.

A walk through TAK's fields

Juan shares:

"Climate is everything when it comes to guaranteeing our quality, especially our ability to grow optimally all year long. Guatemala is known as the land of eternal spring for a reason. A constant spring-like climate allows our foliage to grow at its prime year-round. This creates consistency in our plantations, which translates into quality and the assurance that we will not fail on any order at any time of the year – whether due to frost, tornadoes, hurricanes, or extreme drought."

Post-Harvest Performance Done Right

Post-harvest performance is a direct reflection of decisions made in the field and the discipline applied throughout the operation. At TAK, measurement is used as a tool for understanding, accountability, and continuous improvement across every stage of production.

"Anything that can be measured can be managed, and therefore improved. Our production areas are evaluated by the number of rolls per acre, which gives us a precise reading of plantation performance, health, and longevity. This is further broken down into rolls per bench – 70 benches per acre – which is directly linked to shoot projections quantified eight weeks in advance. When we look specifically at post-harvest, we measure our harvesting teams by rolls cut per hour, rolls classified per hour, and rolls packed per hour. These metrics are valuable not only for tracking our teams, but also for understanding the real performance of each specific lot.”

And lastly, what criteria does TAK look for in foliage before harvesting?

Before any foliage is harvested, careful evaluation ensures that only material capable of performing through transport, handling, and use is selected. This step is essential to protecting consistency and maximizing post-harvest results, as the conditions of each leaf at the moment of cutting directly influence its durability and efficiency throughout the supply chain.

To finalize the facts, Juan Cuellar proudly and insightfully shares:

"Overall, the primary focus is quality. Maturity is key – cutting a leaf at its optimal stage makes sure that many of the characteristics valued in our foliage are preserved. Hydration is equally important; the plant must be fully hydrated and healthy to withstand transportation to its destination. Zero defects are essential: our leaves are carefully inspected by trained eyes that evaluate each one, ensuring maximum utilization once they reach our packing facilities and reducing the time between cutting and placement in the cold room."

Foliage quality is determined by much more than just look in a global supply chain where performance, consistency, and dependability are non-negotiable. It is the outcome of production systems based on measurement, responsible use of climate advantages, and disciplined decision-making at every level, from field planning to post-harvest execution.

The hands that grow the legacy

TAK's strategy shows that consistent foliage is grown and produced with consideration for the crop, process accountability, and an awareness that each cut leaf conveys the expectations of the market it serves. When foliage is created with this degree of purpose, it becomes a reliable part of expert floral work and is no longer replaceable.

Photos courtesy of TAK.