Growers are continuously looking for ways to improve their way of growing; How can I increase my production? What can I do to improve the quality of my products? Is there a way I can use fewer resources to produce more cost-effective and sustainable? One of the techniques growers are using today are Signify’s LED systems and its light recipes. It helps growers to increase production at a higher quality and in a more sustainable way!

Signify’s LED systems and its light recipes

The road to success

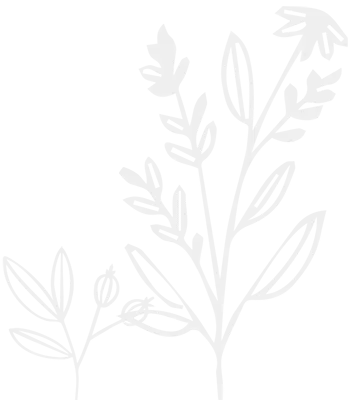

More than 40 years ago growers started to grow their crops using HPS artificial light. They found that increasing the light hours and intensity has a positive effect on production and quality. Then, 14 years ago, Signify (formerly known as Philips lighting), was the frontrunner in pioneering a new technology, with significant advantages over HPS. LEDs don’t emit as much heat as HPS and are much more energy-efficient. More importantly, LEDs enable the development of customized light recipes. In cooperation with Universities and partners, Signify developed over 150 light recipes across different horticultural crops, creating the perfect light spectrum (the combination of different light colors) for each crop. Roses, for instance, have different light needs than chrysanthemums. The possibilities with LED have many advantages for the whole value chain from breeder to consumer.

Producing more sustainably by using fewer resources

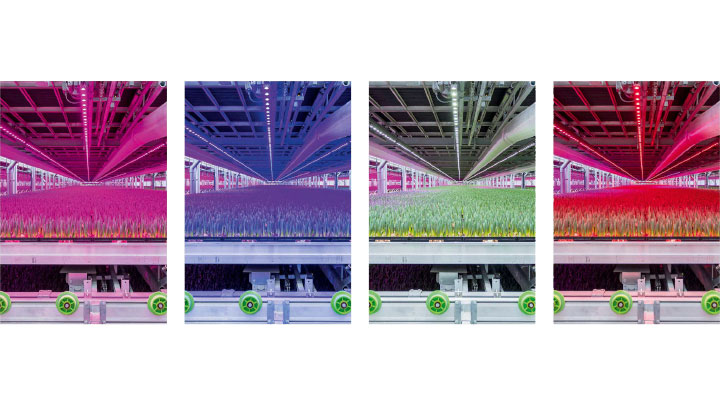

LED is a very energy-efficient lighting technology, enabling growers to reduce energy usage by up to 50% compared to growing with HPS. Thanks to LED growers can apply the most effective spectrum for their crop, reducing the waste of light resources that the plant doesn’t use. Also, growers often open their greenhouse windows to get rid of the excess heat generated by the HPS, also resulting in CO2 exiting the greenhouse. As LED generates less heat the grower can keep the CO2 inside the greenhouse. For these reasons Arcadia, one of the leading chrysanthemum producers in the Netherlands, decided to invest in LED. With a double screen and the latest dehumidification techniques, they were creating the optimal climate to grow chrysanthemum whilst saving energy. The investment in LEDs was for them the logical next step as this answers their conscious consumer’s increasing demand for a more sustainable way of producing plants and flowers. Also, at the plant propagation phase, our customers see a strong impact of Signify LEDs on sustainable production. To keep their plants more compact, growers use PGRs (Plant Growth Regulators). With LED they can reduce the use of these PGRs and produce more sustainably. Lead Grower of Propagation at Lucas Greenhouses Tom Gunther:

“LED lights have helped us improve many parts of our propagation program. Specifically, height control on liners, fewer growth regulators required. Which is good for us and good for our downstream customer.”

Creating better quality year-round

Due to the differences between the seasons, it can be challenging for growers to maintain the same flower quality all year-round. As Daniel van den Nouweland, General Director of Marjoland, the largest rose grower in the Netherlands says:

“the secret to growing the perfect rose is all about doing everything right, every day”.

Signify’s LED modules allow him to increase light levels without generating additional heat, so his roses are grown under stable light conditions all year-round. This way they can guarantee consistent quality and vase life, resulting in happy returning customers and consumers. Wouter van der Harg, Manager at Leo van der Harg BV has the same experience in his potted rose greenhouse.

“Because LEDs do not generate any radiant heat, it is possible to control the temperature and the lighting separately. The investment will pay for itself straight away, not just because of the energy savings but also because of the improvement in plant quality. We believe that LEDs are the future. That is why we are opting now for LED lighting. This will mean our business is ready for the future."

Increased production

LED is also a great solution for growing alstroemeria, a crop that loves higher levels of light, but cannot handle the heat that well! That’s exactly why grower H.M. Tesselaar Alstroemeria, a Dutch specialist in the cultivation of alstroemeria, decided to invest in Signify LED lights for three years in a row. Manager Melvin Tesselaar:

“With this solution, we can increase the lighting intensity and lighting hours required by our alstroemerias, while maintaining acceptable heat levels. This helps us improve both the quality and yields for our crops all year-round.”

Another example of increased production with Signify LED lights can be found at Iwasaki Bros., Inc. one of the largest wholesale growers of bedding plants & perennials, located in Hillsboro, Oregon in the US. Jim Iwasaki, Owner and General Manager, saw an improvement in the rooting speed by 5-7 days.

“We’ve shortened our crop cycle by up to three weeks, which means we can get an extra cycle of plants through a greenhouse and that’s very exciting, very profitable.”

LED is ON!

As with all new technology, when LED was introduced in horticulture as the alternative for HPS there was some doubt whether growing with LEDs would be possible. However, throughout the years Signify has worked extensively with over 400 growers in 43 different countries in crops varying from gerbera to potted rose, from cucumber to cherry tomato. To give you an idea: if you would line up all the LED modules we’ve sold in the last 14 years they would stretch over 3,460 kilometers! That’s the distance from Amsterdam in the Netherlands to Cairo in Egypt! It’s only a matter of time before we’ll be able to cross the equator! Signify LED brightens up the entire Floriculture value chain! Udo van Slooten  Business Leader Horticulture at Signify

Business Leader Horticulture at Signify