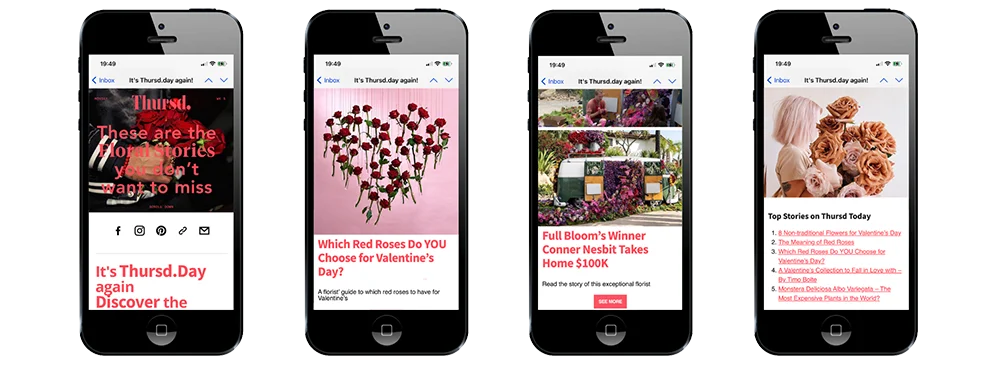

What happens in Kenya does not (always) stay in Kenya. At least not with United Selections. Their breeding facilities in Nakuru are the true starting point of all the processes and development stages that continue not just in Kenya, but also around the world. What's for sure: It all starts here in Africa. Here's an in-depth look inside given by the farm's process manager Lars Schalkers, of this forward standard and spray rose breeder.

United Selections in Nakuru, Kenya

Tucked into the highlands of Nakuru, Kenya, at about 2,150 meters above sea level, at a 4 -to 5-hour drive from the capital Nairobi, you'll find United Selections' rose breeding facility. It might look all quiet and tranquil when you arrive at the premises, with exotic birds lazily walking on the lawn and two happy dogs that welcome you into their home. But step into one of the greenhouses, and you're at the epicenter of a full-circle rose breeding operation. Here, from breeding to propagation to showtime, it's all happening under one roof. Quite literally.

United Selections is among the few—if not the only—breeders that handle the entire process right here in Kenya. That includes the initial breeding, propagation, selection, evaluation, and eventual promotion of new varieties. Having everything localized means they can breed and test varieties directly in equatorial light conditions and at altitude—an advantage for global performance prediction.

The Showhouse Is More Than Just a Pretty Face

The first door Lars Schalkers opens is the one that leads to the neat and clean showhouse.

Lars, by the way, didn’t grow up in the rose world. He came from a background in hospitality and food, with stints in China and Thailand, including running a bakery with his grandfather. It was United Selection's CEO, Jelle Posthumus, a long-time friend, who spotted Lars’s knack for managing teams and systems. And now, after a crash course in rose breeding, Lars is the guy making sure all departments—crop management, propagation, breeding, and selection—work in sync.

Out of the 3.5 hectares on the farm, about 1 hectare is dedicated to the showhouse and budwood greenhouses. This is where all commercial varieties are put on display. It's not just for show, though. While the flowers look polished and camera-ready, they are still part of an active data collection process. Every stem is monitored for performance, disease resistance, vase life, and overall behavior.

Take Rose Rise & Shine, for instance. This golden-yellow stunner has been going strong both in Kenya and in South American markets. Some varieties, like Rose Lighthouse, don’t always perform equally well across regions—a reminder of how altitude and microclimate can make or break a variety. That’s exactly why United tests both at their Nakuru base and then further through sister facilities in Ecuador and Colombia.

From Lab Bench to Budwood Bed

The whole process kicks off in what Lars fondly refers to as "the kitchen." This is the birthplace of future varieties. Every cutting, every sprout is tracked and coded, forming the base for years of selection work. According to Lars, it can take up to eight years before a promising seedling makes it into the commercial range.

Propagation is where the magic continues. The farm only uses clean, in-house material to avoid issues like agrobacterium and to ensure traceable, consistent quality. "We know what goes out and how," Lars explains. Orders vary from trial batches to full commercial consignments, depending on available budwood. The farm supplies global markets, including recent orders heading to South Korea.

Even for varieties in their early days, like those in the three-bed setup in the showhouse, the process is detailed. These beds help scale up propagation internally. Customers request material from Nakuru because of the quality guarantee. Some are even willing to wait longer for deliveries, knowing they’re getting solid, clean stock.

Selection and the Eye of Paul

Paul de Bruin, United Selections’ breeding director, visits the Nakuru farm every six to seven weeks. You've read about him before when he was interviewed on the Ecuador farm during the 2024 Expo Flor. His role? Evaluate, select, and guide. With selection managers and crop managers prepping the farm ahead of time, Paul can go straight into review mode. Each visit includes checking current varieties and spotting potential future hits. It's a rhythm the entire team is used to and one that brings structure to the year.

One major calendar moment is the end-of-June selection week. Just a few weeks after IFTEX, the team gathers for a farm-wide review. Varieties that perform well get a green light; others are removed or adjusted. New varieties like Rose Hot Wave—a hot pink, thornless type—offer fresh alternatives to the successful Madam series. This continual evolution of the portfolio is what keeps United Selections ahead.

Blossoms, Buds, and Market Needs

The Blossoms spray rose series is a familiar face to many florists. Recognizable by name, style, and above-average large flowers, it now spans shades from champagne to purple. Spray Rose Golden Blossoms and Snowy Blossoms are also gaining traction. The aim? A complete package that works for both retail and high-end floral design.

Another market-driven focus is vase life and shipping resilience. With rising airfreight costs, sea freight is on the rise, especially for large-scale retail clients. That means testing each variety for travel durability—up to four weeks in some cases—is no longer optional. United collaborates with transport companies to push for innovation, like vacuum containers and nitrogen boosts.

People and Perspective

There’s a certain honesty in how Lars talks about the farm. The team includes around 150-160 staff—a lot for 3.5 hectares. But it’s a breeding facility, not a priority production zone, so the density is intentional. It also means there's an ongoing focus on hygiene, training, and shared responsibility. Lars encourages local managers to take ownership, a shift from older structures where too much depended on one person.

And maybe that’s what stands out most at United Selections in Nakuru: a sense of clarity in process, people, and product. Whether it’s the search for the next big white or red rose, extending its popular Blossoms series of sprays, or refining propagation practices, everything happens with both precision and a grounded mindset. No frills, no fluff—just good breeding, done right. Team effort and customer leadership towards "breeding a colourful rose future."

In the header image, Lars is in the field with the yellow Rose Rise & Shine.