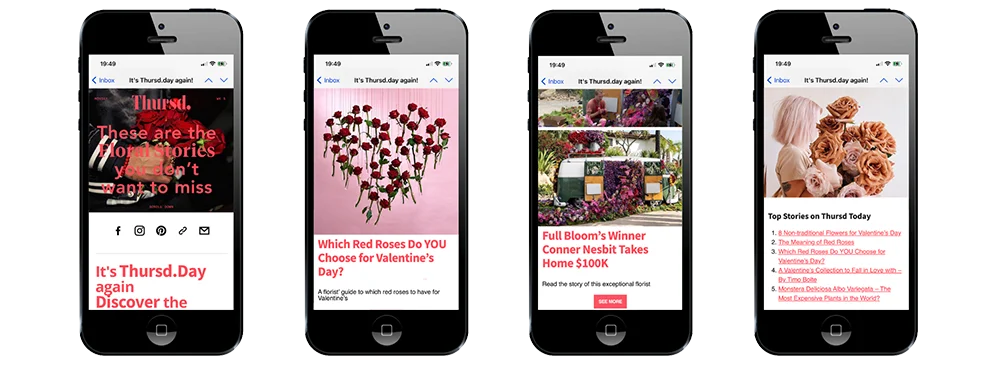

Chances are, you have ever thought of a flower business where nothing wilts unnecessarily. Where employees thrive alongside the floral products they produce. Where no water is wasted, no energy is squandered, no labor is spent for nothing. And essentially every flower serves its purpose before gracefully fading away back to the soil.

This is the often understated but essential field of inventory management. It is the space where the right numbers save the floral business's bottom line and contribute to sustainable practices. While it might sound just pragmatic, it coordinates entire operations where eco-friendliness, worker dignity, and business vitality thrive concurrently.

Smart Inventory Management Acts as the First Line of Defense

When we think of sustainable floriculture, minds often drift toward practices like pesticide-free cultivation, carbon-neutrality, or fair wages. These certainly matter. But proper inventory control acts as the central nervous system connecting environmental conservation, employee welfare, and economic viability in the floriculture industry.

Starting with waste: because in floriculture, waste is everything that sustainability isn't. Every flower that doesn't reach a customer means resources down the drain—literally. Consider the water footprint alone: a single rose requires roughly 10-13 liters of water from farm to vase. Multiply that by thousands of unsold stems, and the environmental cost adds up faster than one would think.

Flowers possess an unfortunate characteristic that keeps everyone in their value chain perpetually alert: they are perishable. Unlike ceramic vases gathering dust on shelves, roses won't graciously wait around for Valentine's or Mother’s Day if they arrived in January. They wilt sooner.

When flower businesses lack robust tracking systems, they inevitably stumble into over-ordering. Wilted flowers destined for landfills release methane during decomposition, a greenhouse gas considerably more potent than carbon dioxide. Meanwhile, all the water, energy, and labor invested in cultivating those flowers evaporate into waste.

Just as Sustainabloom—the initiative that helps businesses embrace sustainability in the world of floriculture with a friendly touch—puts it, floral businesses that have a firm grasp on accurate inventory needs will see it in their bottom line. It saves money, optimizes storage space, and helps one remain prepared for changing consumer markets. It also plays a key role in sustainability.

Smart inventory management acts as the first line of defense. When you know exactly what's moving, what's sitting too long, and what your customers actually want, you stop over-ordering. You stop playing guesswork games with these perishable products that often have just slightly over a week of shelf life.

Real-time tracking systems and demand forecasting tools help growers and distributors make even production with actual market needs. Advanced analytics platforms now predict demand by analyzing historical sales data, seasonal patterns, weather conditions, and even event schedules. Proper stock rotation—first in, first out (FIFO)—therefore means flowers move at their freshest.

Some operations even report waste reductions approaching 40% after implementing comprehensive predictive systems, which means countless gallons of water conserved, reduced pesticide applications, and lessened emissions from flower production.

The Carbon Footprint of Poor Planning

Poor inventory planning means ordering emergency shipments, rush deliveries, and last-minute logistics scrambles that could have been avoided with better foresight. When you constantly react rather than plan, you end up with inefficient solutions. Every unnecessary delivery run, every half-empty truck, every expedited shipment adds carbon emissions that proper inventory management could have prevented.

Accurate tracking allows businesses to consolidate shipments, optimize logistics routes, and plan transport schedules that maximize efficiency, meaning you're not constantly firefighting stockouts or racing against wilting deadlines. Better yet, accurate forecasting allows businesses to choose transport methods based on actual timelines and not artificial urgency.

Still, yet, energy consumption in flower cold chains is substantial. Flowers need consistent cooling from post-harvest through transport to retail. Poor inventory management means flowers sit longer in coolers, consuming energy while their value depreciates, because overstocking, essentially, means running more cooling capacity than necessary.

Precise inventory control reduces cold storage time by improving turnover rates, which means you don’t keep flowers in the cold facilities "just in case," but rather move the products strategically, minimizing the time between harvest and sale. Also, temperature-controlled storage demands significant energy, and smart inventory systems optimize these conditions using real-time data to adjust settings that prolong flower life while reducing power consumption.

Where Inventory Management Meets Worker Welfare

Sustainable floriculture demands more than environmental metrics. It requires acknowledging the people who tend, harvest, pack and arrange these flowers. Unpredictable demand leads to unpredictable work schedules. Farm workers face overtime crunches during unexpected rush orders, and then sit idle when overstock means reduced production.

Such erratic and chaotic inventory practices create chaotic workplaces. But good inventory management smooths out these peaks and valleys. When tracking relies on scribbled notes and guesswork, employees face unnecessary stress, extended hours during crisis moments, and exposure to blame when shortages emerge.

Well-implemented systems provide clarity. When farms can predict orders with reasonable accuracy, they can offer workers stable schedules and consistent hours. Pack-house teams operate efficiently rather than scrambling through disorganized stockpiles. Staff knows precisely what's available, what needs attention, and what requires ordering. Everyone from the field worker to the logistics coordinator benefits when the supply chain operates on concrete data instead of daily frenzy.

Employee training programs focused on inventory management deliver benefits on this aspect. Staffs who understand flower and input orders, precision irrigation, integrated pest management, and proper post-harvest handling can be better environmental leaders while improving their own job security. Growers implementing data-driven practices after workforce education can report significant savings alongside improved working conditions. Knowledge empowers workers to contribute greatly toward sustainability goals, creating purpose, not just task completion.

Also, fair labor practices increasingly intertwine with inventory transparency. Fairtrade-certified flower farms generally comply with extensive social regulations promoting equitable working conditions. These certifications mean little if inventory chaos still creates stressful working conditions. Inventory systems designed with worker welfare in their planning help businesses maintain these standards consistently.

The Economic Logic That Sustains Sustainable Practices

Sustainability initiatives must make financial sense, or flower businesses won't sustain them. Inventory management provides the economic basis supporting these environmental and social commitments.

Strategic purchasing guided by accurate inventory data prevents the financial hemorrhaging caused by spoilage. When flower businesses analyze previous sales patterns and adjust orders accordingly, they avoid the seductive trap of bulk markdowns on flowers inadvertently destined for the compost bin in operations without proper inventory management. Systems like point-of-sale can, for instance, automatically adjust stock levels as flowers leave the facility, sending alerts before popular varieties run low.

Circular economy principles also transform potential waste into assets. Composting floral waste creates nutrient-rich soil amendments that businesses can use internally or sell. In this context, some flower operations often partner with local farms, converting their organic waste into agricultural resources for farming use, while reducing disposal costs.

There is also the element of route optimization software. Informed by inventory data across different locations, it reduces transportation emissions while improving delivery freshness. Knowing precisely which regional hub stocks which flowers allows businesses to minimize mileage, cut fuel expenses, and ensure flowers arrive in peak condition.

Modern inventory management systems can also track more than just flowers. They monitor packaging materials, identify reusable containers, manage compost programs, and coordinate with circular economy initiatives. Some progressive operations now track sustainability metrics alongside traditional inventory data—water usage per stem, carbon footprint, and waste percentages by product category—turning inventory management into a sustainability dashboard.

Making Systems Work

Implementing effective inventory management for sustainability requires viewing the operation broadly. Technology provides tools, but human commitment makes them effective. Staff needs training not just in operating software, but in understanding why accurate tracking matters for environmental outcomes and fair labor practices.

Smaller operations might feel overwhelmed by sophisticated systems, yet scalable solutions exist. Even basic practices like daily cooler checks organized by freshness, midday inventory reviews, and simple spreadsheets tracking usage patterns substantially reduce waste. The goal isn't one-off perfection but continuous improvement.

Transparency throughout the supply chain strengthens these efforts. Blockchain technology now documents flower origins, verifying sustainability claims and ensuring ethical sourcing. Because customers increasingly demand this visibility, inventory tracking provides a competitive advantage.

In essence, it is all about the mundane, yet essential, work of knowing what you have, where it is, and where it needs to go. Inventory management might not sound as exciting as solar-powered greenhouses, but it is just as important for building a sustainable flower business, having it in mind that sustainable flowers are those that reach customers and consumers at the right time, through an efficient supply chain, with minimal waste.

Feature image by @antonspaargaren. Header image by Daniel Spilka.